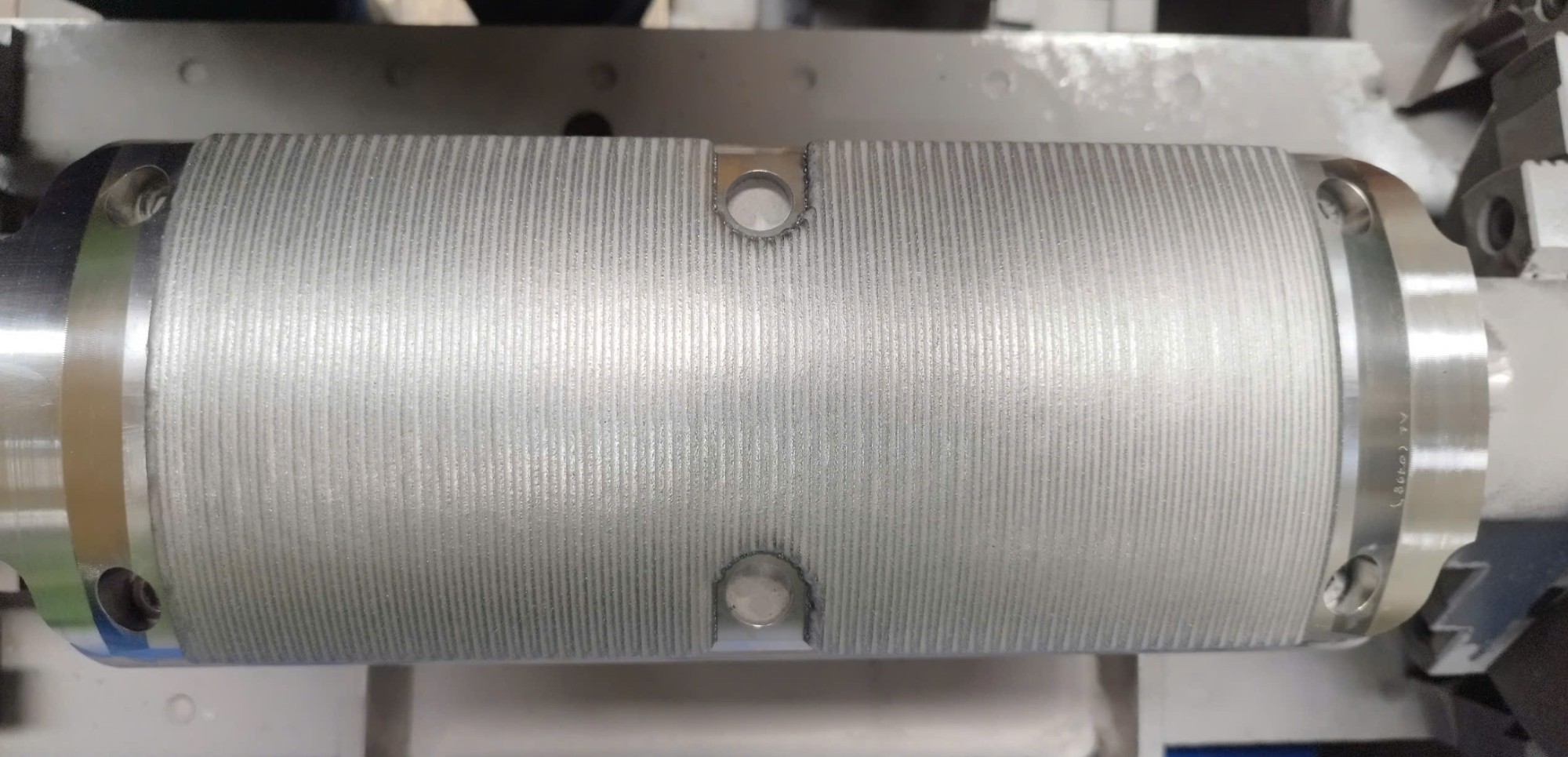

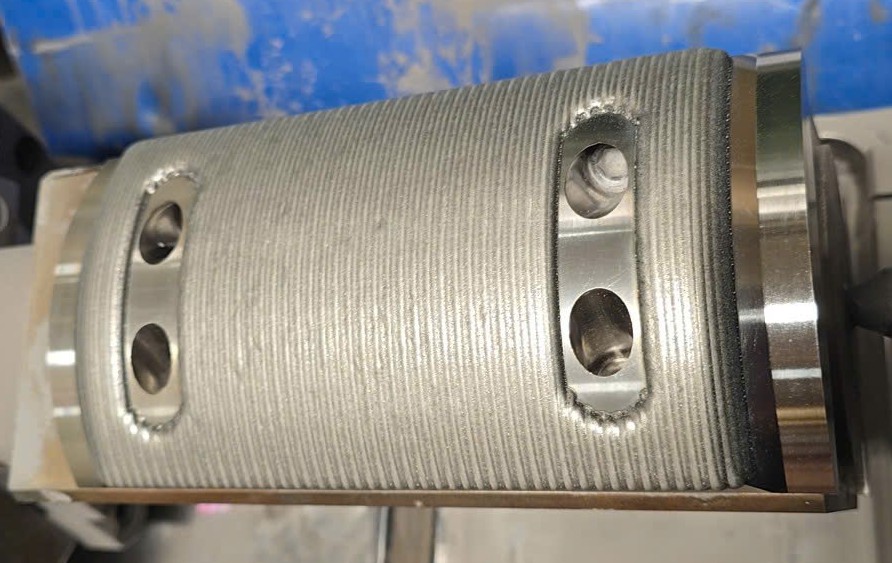

Laser Cladding uses a high-power laser to fuse a coating material onto a surface. It enhances wear and corrosion resistance, and is widely used for surface engineering of high-value components in tooling, aerospace, and energy industries.

Machine capabilities :

Laserline LDM 6000-60 Diode Laser: 1 set OD & 1 set ID

* Manufacturer: Laserline GmbH, Germany

* Max. output power: 6,000 W

Laser Cladding Applications:

* Max OD cladding over 20" in diameter & over 400" in length, with fixture support available for larger diameters

* ID Cladding up to ID 1.5” Min X 25” Depth

* Various Cladding Powders: Tungsten Carbide Blend with Nickel-based matrix, Stainless, Nickel Alloy, Cobalt Based (Stellite 6, Stellite 12)

ID Cladding Tool 1500: Deep Bore Laser Clad Head

* Up to ID 1.5” Min X 25” Depth

* 1.8kW max. Power, compatible with powder

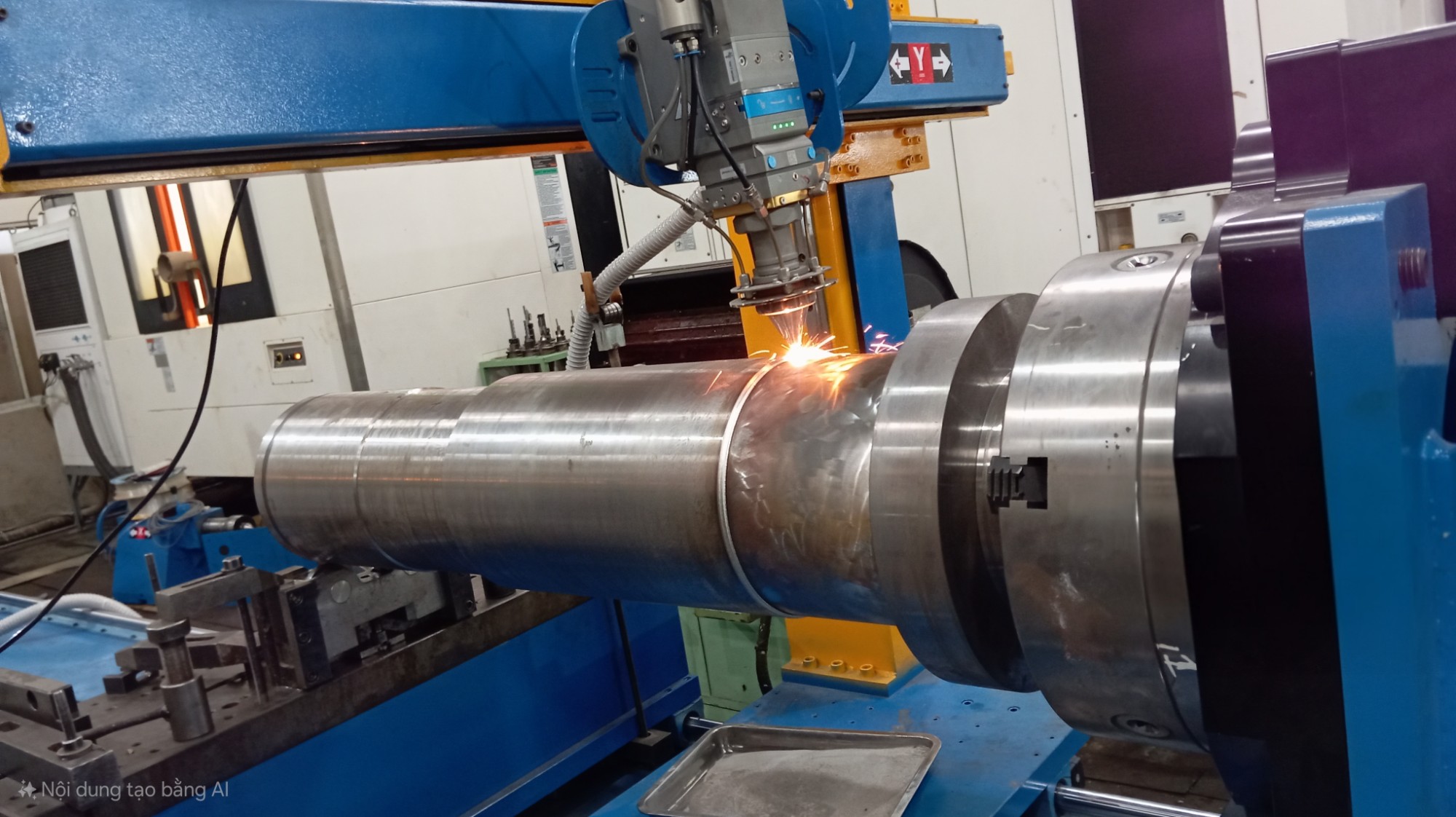

Laser cladding operations can be integrated with a KUKA robot:

* Industrial Robot KUKA KR 50 R2500

* 6 Aixs Robot & Reach: 2500 mm

* Applicable for long shafts over 5 meters